Page 48 - TBN-2014-3

P. 48

Continental Brings Retreading into the Space Age wi

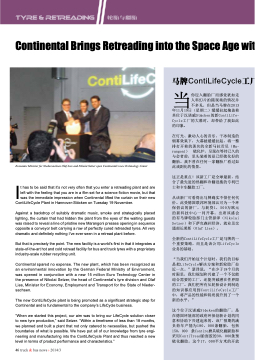

Economic Minister for Niedersachsen Olaf Lies and Nikolai Setzer open Continental’s new Technology Center

It has to be said that it’s not very often that you enter a retreading plant and are left with the feeling that you are in a film set for a science fiction movie, but that was the immediate impression when Continental lifted the curtain on their new ContiLifeCycle Plant in Hannover-Stöcken on Tuesday 19 November.

Against a backdrop of suitably dramatic music, smoke and strategically placed lighting, the curtain that had hidden the plant from the eyes of the waiting guests was raised to reveal a line of pristine new Marangoni presses opening in sequence opposite a conveyor belt carrying a row of perfectly cured retreaded tyres. All very dramatic and definitely nothing I’ve ever seen in a retread plant before.

But that is precisely the point. The new facility is a world’s first in that it integrates a state-of-the-art hot and cold retread facility for bus and truck tyres with a proprietary industry-scale rubber recycling unit.

Continental spared no expense. The new plant, which has been recognized as an environmental innovation by the German Federal Ministry of Environment, was opened in conjunction with a new 15 million Euro Technology Center in the presence of Nikolai Setzer, the head of Continental’s tyre division and Olaf Lies, Minister for Economy, Employment and Transport for the State of Nieder- sachsen.

The new ContiLifeCycle plant is being promoted as a significant strategic step for Continental and is fundamental to the company’s LifeCycle business.

“When we started this project, our aim was to bring our LifeCycle solution closer to new tyre production,” said Setzer. “Within a timeframe of less than 18 months, we planned and built a plant that not only catered to necessities, but pushed the boundaries of what is possible. We have put all of our knowledge from tyre engi- neering and manufacturing into the ContiLifeCycle Plant and thus reached a new level in terms of product performance and characteristics.”

46 truck & bus news › 2014/3

马牌ContiLifeCycle工

当你迈入翻胎厂而感觉犹如走 人科幻片拍摄现场的情况并 不多见,但是当马牌在2013 年11月19日(星期二)缓缓拉起掩盖着 其位于汉诺威Stöcken的新ContiLife- Cycle工厂的大幕时,却带给了我如此 的印象。

在灯光、激动人心的音乐、干冰制造的 烟雾效果下,大幕被缓缓拉起,将一整 排打开着的著名的全新马拉贡尼(Ma- rangoni) 硫化炉,呈现在等待已久的 与会者前,里头装着的是已经硫化好的 翻胎。我不曾在任何一家翻胎厂看过如 此戏剧化的情景。

这正是重点!该新工厂是全球最新,结 合了最先进的热翻和冷翻设施的专利巴 士和卡车翻胎工厂。

从该新厂可看得出马牌确实不惜任何代 价。此受德国联邦环境部认可为一个环 保倡议的新厂,与耗资1,500万欧元 的新科技中心一同开幕。出席该盛会 的有马牌轮胎部门主管瑟泽(Nikolai Setzer)和下萨克森州经济、就业及交 通部长莱斯(Olaf Lies)。

全新的ContiLifeCycle工厂是马牌的一 个重要策略,而且是该公司LifeCycle 业务的基础。

“当我们开始这个计划时,我们的目标 是把LifeCycle解决方案和新轮胎厂拉 近一点。”瑟泽说。“在少于18个月的 时限里,我们规划和兴建了一个不仅能 迎合需要的工厂,还能突破潜在性界限 的工厂。我们把所有从轮胎设计到制造 的知识都应用到ContiLifeCycle工厂 中,将产品的性能和特质提升到了一个 新的水平。”

这个位于汉诺威Stöcken的翻胎厂,是 在德国环境部的政府环保创新计划的同 意和协助下兴建起来的。该厂预期的满 负荷年产能为180,000条翻胎,包括 150,000 条Contire磨具硫化翻新胎和 采用ContiTread胎面胶的30,000条预 硫化翻胎。这个17,000平方米的开放

t

厂